|

its one of the biggest employers (with around 850 staff) and a big part of the community. the latest sugar and sweetener products coming out. We have a new crane on the jetty, better ships coming in and the river is keeping busy too – with bigger cruise ships and other craft visiting. We’ll keep using the river,

“And we send one ship a month to Norway, the only place we export directly to. One interesting fact is that our biggest demand for golden syrup, outside of the UK is Yemen.”  Meanwhile, a mile away, Lyle’s Golden Syrup and associated goods is similarly packed up and shipped out (more than a million tins of syrup every month). The company has 285 separate products leaving Silvertown and its neighbouring site.

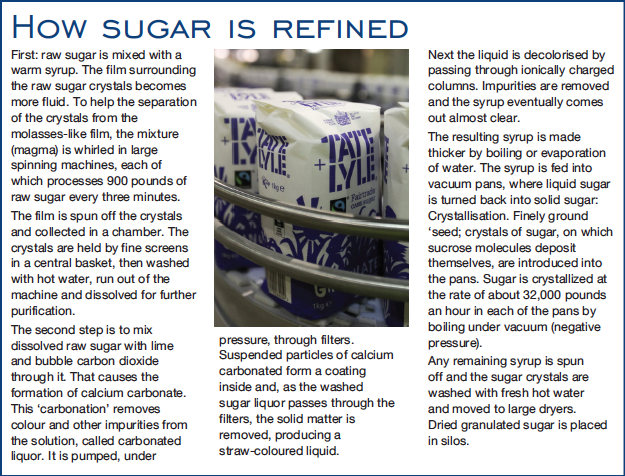

As well as its sugar duties,  How it’s processed “Granulated white sugar is our most popular product without a doubt”, says Joe. We do 1kg packs that everyone’s familiar with, and then there are bigger measurements, one-tonne bags for instance, which are bought in bulk by food manufacturing customers and bakeries, that sort of thing. Joe says: “Our 1kg packing machines can pack 125 bags per minute, that’s around 7.5 tonnes per hour. And the one-tonne packing line can get through 25 tonnes every hour.” The lightning-fast machines safely seal and stamp the goods which are then trucked to a multitude of UK locations. The stamp of every pack of sugar includes the letter ‘T’, meaning Thames. |